Wooden Crane [Mini -> Mega]

ME-0093: Design for Fabrication – Final Project

Task

Design for Fabrication was by far my favorite undergraduate course at Tufts. We explored a range of fabrication methods and mediums, discussing the design considerations that are involved when deciding which to use when and where. My ability to critically think about a workspace, goal, and limitations to explore potential solutions was refined in this class.

For our final project, our professor challenged us to create a wooden crane using plywood and 2″x8″ wood planks. This crane needed to grip onto a cinder block weighing nearly 40 lbs, lift it from the ground and transfer it onto a platform with specified clearance. The crane needed to be completely human-powered.

After the first crane, the professor surprised us with the next challenge: an even bigger crane which was to lift a heavy wooden box containing our professor himself, or any unwitting volunteer.

My partner worked side-by-side to design and fabricate these two cranes. I was the lead designer for the gravity-grip claw and the trigger mechanism we used to activate it.

Mini Crane

The general shape and design of the crane was the first step. We decided to create a long length supported near the middle by a group of triangular supports and a claw with a grip that would be strengthened as more weight was pulled down.

This was the biggest woodworking project either of us had worked on before. It also required a substantial amount of wood, of which there was a limited supply hounded by high demand, so we had to strictly abide by the age-old proverb, measure twice and cut once.

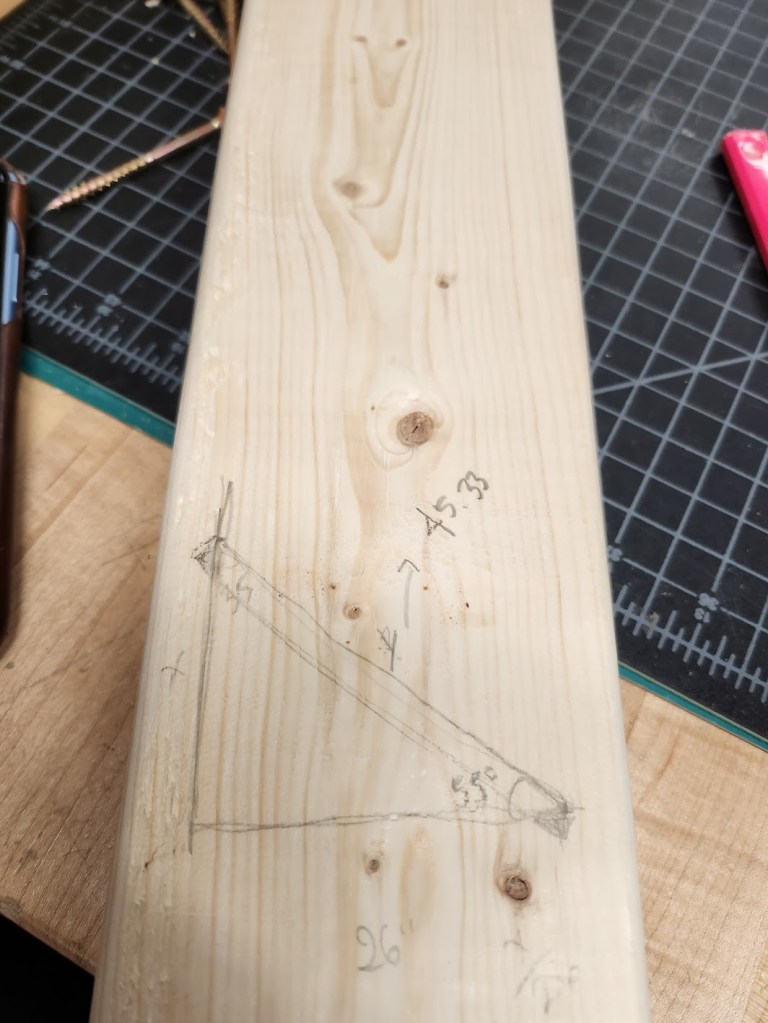

Many calculations and measurements were done on paper and wood to decide on the lengths and angles of each part. We performed experiments with the cinder block to determine the ratio of length we needed between us and the pivot point and between the pivot point and the end effector.

Then my partner and I divided up the tasks. I designed and built the claw and the opening/closing mechanism while he worked on the main frame.

The claw used two Z-shaped pieces, fixed at the mouth but hinged at the the top. They connected at the middle, freely rotating to open and close as the claw widened and got shorter or became narrower and longer. Once positioned onto an object, the strength of the grip increased with the weight of the load as it pulled the teeth of the claws down with more force. The mechanism for opening and closing the claw was a length of sailing string tied around the middle pivot, which was the crucial operating piece.

Finally we put it all together and added the triangular supports to the base.

This is where we tested the claw without the base. My partner held the contraption steady while I manipulated the handle to open and close the claw.

This was the crucial moment when we realized more calculations would be necessary to balance the weight of the cinder block with the moment we could exert with a longer section between the operator and the pivot.

Testing with the new claw contraption and base.

From this trial, we decided to make a handle to make it easier to pull the string instead of having to wrap it around our hands when operating the crane. The force required to open the heavy claw make pulling the thin string uncomfortable over time.

Additionally, I realized arm strength would not be enough to comfortably lift the cinder block and suggested that we implement a step to leverage the operator’s weight in aiding them with the lift. Some teams opted to make a seat on the end of the beam itself, which was another creative approach, albeit a tad harder to mount.

This was the final product, incorporating the base, handlebars, step bar and readjusted beam length. My partner took advantage of the infinitely long surface environment that our professor had given us to help me land the cinder block. Overall, our crane was a great success!

Mega Crane

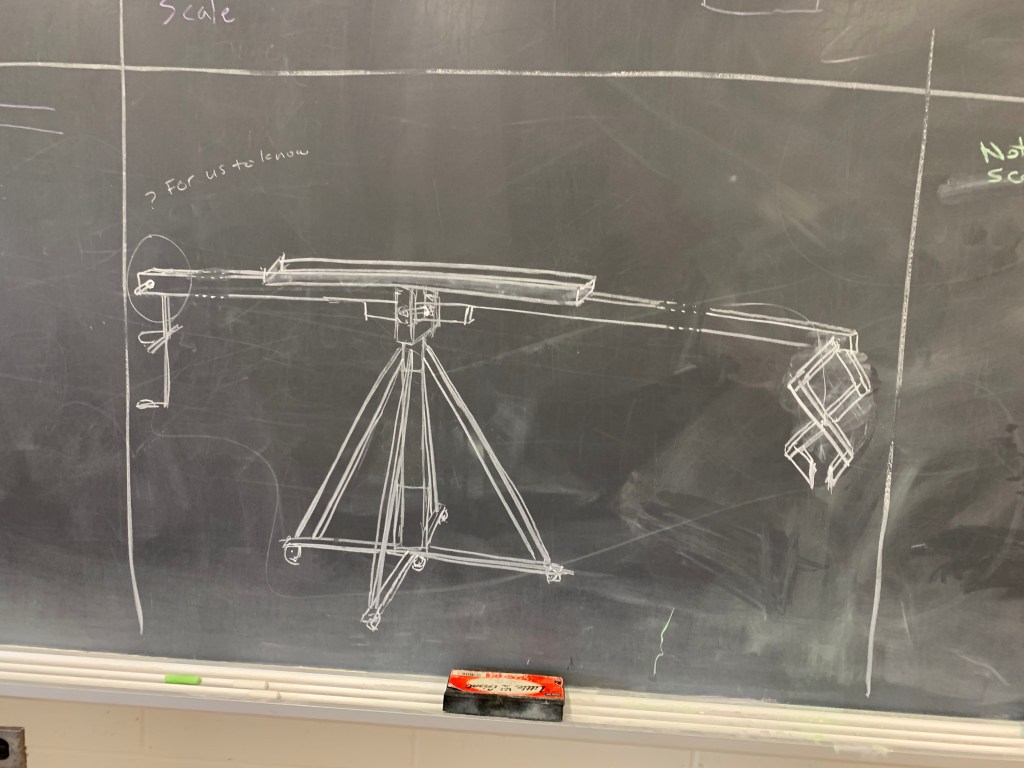

The next challenge was to carry a massive plywood box that our professor had made to seat one unfortunate soul with a hardhat protecting the wrong end from impact. The box needed to be lifted from the bottom of the patio stairs to the top. This challenged us to think even bigger, using massive pieces of wood and fabricating on a scale we had never attempted before. I sketched out our plan in the image below.

The idea was the same as the mini crane, except this time we would need to combine multiple beams of wood because one wouldn’t be long enough for the challenge criteria. We decided on a T-beam to join these lengths together with a beam on top to prevent it from bending. Also, we would need both our weights combined to lift the box as we didn’t have enough space to leverage a longer beam to generate the moment needed for one operator to be sufficient. This meant building a two-seater for the operating end. Additionally, the crane needed wheels and needed to be easily assembled/disassembled so that we could transport it through the doors as we finished building it and readied it for the demonstration. Lastly, the claw needed to be reimagined, using the same gravity-strengthened concept but with more prongs and better gripping surfaces in addition to a larger scale to account for the larger box.

Due to material shortages, my partner and I had to complete the entire build over the course of one day. We preserved the base, which ultimately ended up being the area that fractured first, and built the new components separately, assembling everything at the end.

The mega crane was semi-successful. We were able to lift the plywood box with our volunteer inside, but once we attempted to swing the beam around, the center pole began to fracture. It was composed of thick PVC pipe caged within wooden walls, but the part of the pipe that wasn’t as supported began to deform under the weight and angle of the force. Our trial had to be done without a person inside for safety reasons, though it may have held up.

The handle on this one was made of climbing cord with an anchor to fix it open when needed as it was a lot harder to hold than the mini crane. The claw was immensely heavy, but very sturdy and easily held the box.

This project was one of my favorites up to date. I learned so much about woodworking and was challenged to think outside of the box as we navigated a much larger work space than we were used to. If we’d had more time, I would definitely focus on reinforcing the core of the crane and adjusting the length ratio to make it easier for the operator to lift heavier objects.